When people talk about Olea Kiosks, they usually focus on what we build—smart, self-service kiosks that deliver performance, durability, and design excellence. But this chapter of our 50th Anniversary story focuses on how we build. Because behind every sleek kiosk enclosure and every weatherproof frame is a fabrication shop that has become one of Olea’s greatest strategic advantages.

The Fabrication Roots

We were a small team with strong hands, sharp instincts, and a deep appreciation for craftsmanship. Our shop was a place where raw materials were transformed with skill and pride.

This hands-on foundation still shapes us today. It taught us how to recognize quality without needing to measure it—just by feel, by finish, by sound. It gave us the confidence to design boldly and the humility to improve constantly. And it gave us something many companies today don’t have: an internal culture that respects the work done on the floor as much as the work done in the boardroom.

The CNC Leap

The real turning point came when Frank’s grandfather made a gutsy decision: he bought a CNC machine. At the time, CNC wasn’t widely used in smaller shops. The technology was expensive, the learning curve was steep, and the return on investment wasn’t guaranteed.

But they saw the future —and they wanted Olea to be part of it.

That single machine opened the door to precision cutting, repeatability, and scalability. It was the beginning of a transformation. No longer limited to manual cutting and forming, Olea could now take on more complex projects, fulfill larger orders, and experiment with a new level of design freedom.

Learning by Doing

Buying the machine was one thing. Learning it? That took time and effort.

The team embraced the challenge—teaching themselves how to program, run, and maintain the CNC, while still delivering for customers. That grit paid off. The capabilities of the shop grew quickly. With each new job, Olea got better. Faster. Smarter.

The CNC didn’t just boost productivity—it redefined what Olea could offer clients.

Why In-House Manufacturing Matters

Controlling your own production has never been more valuable. While other companies outsource and wait on third-party suppliers, Olea turns ideas into prototypes in days. If a client needs a custom bracket or a last-minute modification? The answer isn’t, “We’ll check with the vendor.” It’s, “We’ll take care of it.”

Keeping production in-house has also protected Olea from disruptions. During periods of widespread supply chain instability, the shop floor kept humming—because the company wasn’t dependent on others to get things done.

It’s not just about speed. It’s about precision, quality control, and trust. Olea’s clients know that what they see on a drawing is what they’ll get in real life—because it’s all built under one roof.

The People Behind the Process

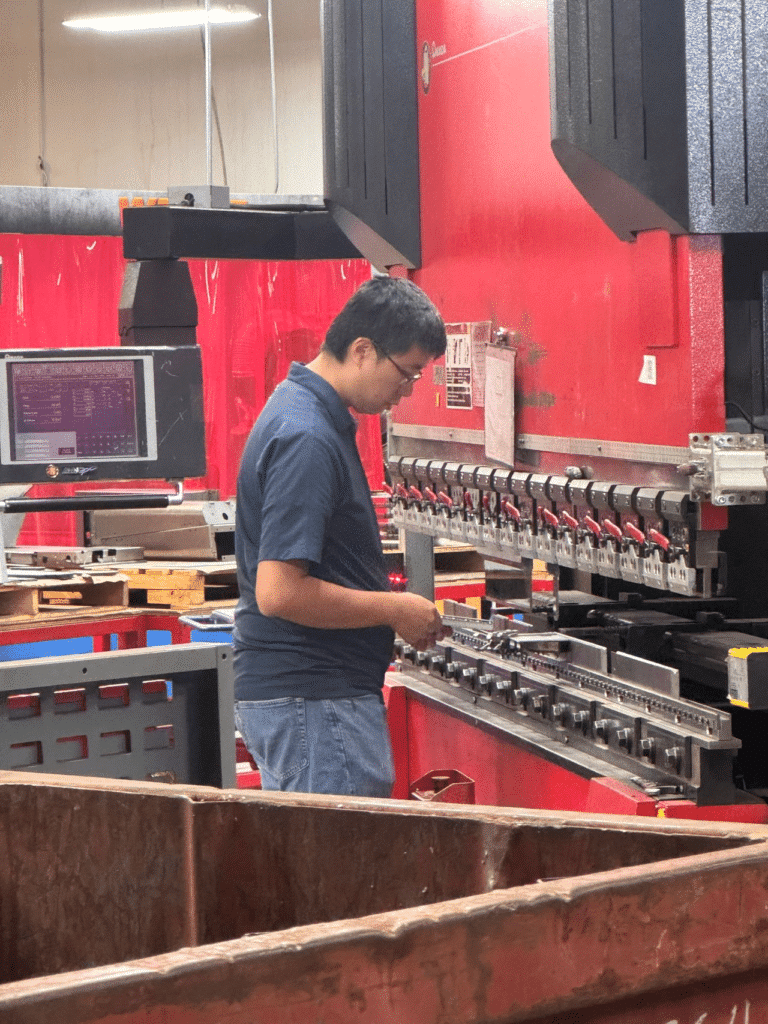

What makes Olea’s manufacturing capability special isn’t just the machines—it’s the people.

The shop team isn’t a back-of-house function. They’re innovators in their own right. They contribute to design decisions. They experiment with new techniques. They help engineering refine ideas. This collaboration has created a dynamic environment where fabrication and innovation go hand in hand.

And it’s not just experienced fabricators. Younger team members are mentored and trained, helping build the next generation of skilled tradespeople. That continuity of knowledge is one more reason Olea’s shop continues to be a source of strength.

Where Ideas Come to Life

Today, Olea’s shop is equipped with advanced CNC machines, lasers, benders, welders, and finishing tools. It’s not just a place to build kiosks—it’s a lab for testing ideas, prototyping new designs, and solving challenges in real time.

The shop is where a concept on a whiteboard becomes a kiosk ready for deployment. It’s where quality gets built in—not inspected later.

Built from the Ground Up

In a world where it’s easy to outsource and offshore, Olea made a different choice. We built from the ground up. We took the harder path of learning, investing, and growing our own capability. And it’s made all the difference—not just in what we deliver, but in who we are. For 50 years, Olea has believed in doing things the right way—even when it’s the harder way. Taking control of our manufacturing was one of those decisions. And today, it’s one of our proudest accomplishments.